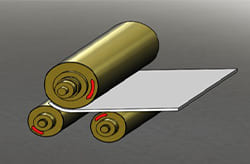

WORK PIECE SQUARING AND ALIGNMENT

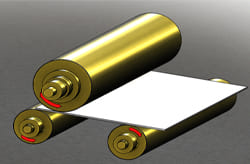

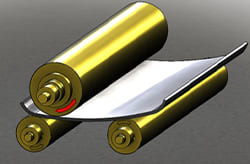

LEADING EDGE PRE BENDING

TRAILING EDGE SQUARING AND ALIGNMENT

TRAILING EDGE PRE BENDING

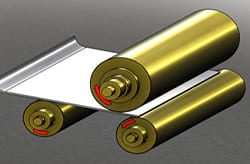

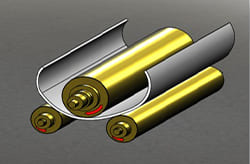

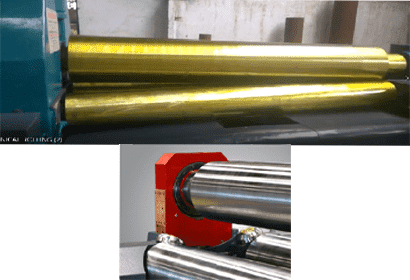

ROLLING STARTS

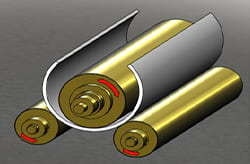

ROLLING IN PROCESS (MULTIPLE PASS)

ROLLING IN PROGRESS

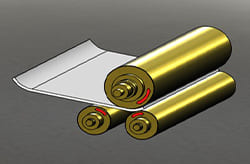

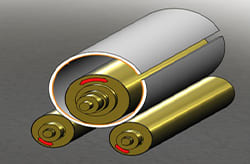

ROLLING COMPLETE

| Sr. No | Particular | Remark |

|---|---|---|

| MODEL CODE | 3 R VANC | |

| 1 | PRE BENDING | YES |

| 2 | ROLLING/BENDING | YES |

| 3 | MAX ROLL WIDTH | 4000 MM |

| 4 | MINIMUM THICKNESS | 20 MM |

| 5 | MAX. THICKNESS | 120 MM |

| 6 | PRODUCTION RATE | NA |

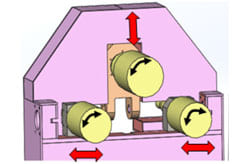

| 7 | SIDE ROLL UP DOWN FOR RADIUS FORMING | BY HYDRAULIC CYLINDER |

| 8 | SIDE ROLL ROTATION | BY HYDRAULIC MOTOR |

| 9 | ROLL POSITION INDICATOR | PLC & HMI |

| 10 | ALL FUNCTIONS ACTUATION | PUSH BUTTON |

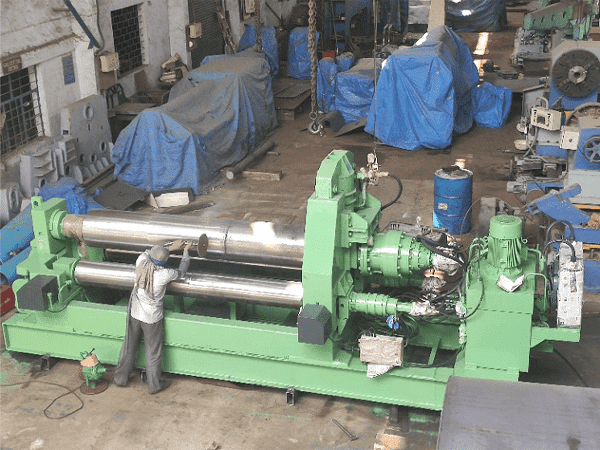

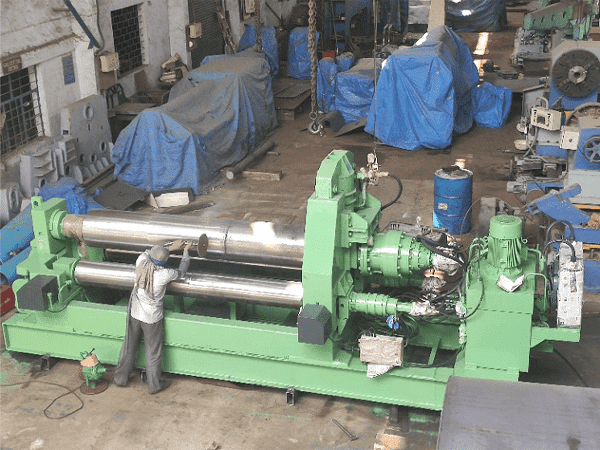

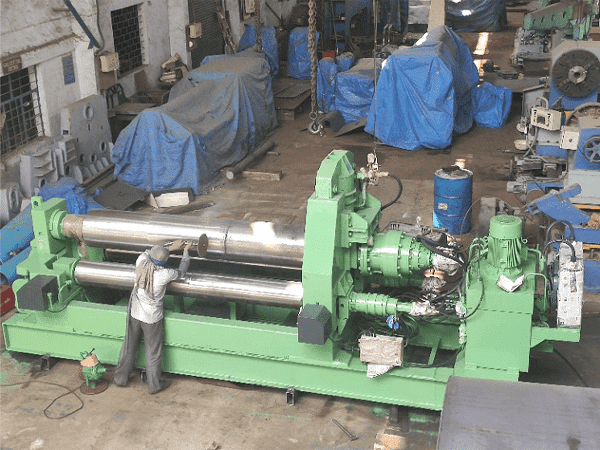

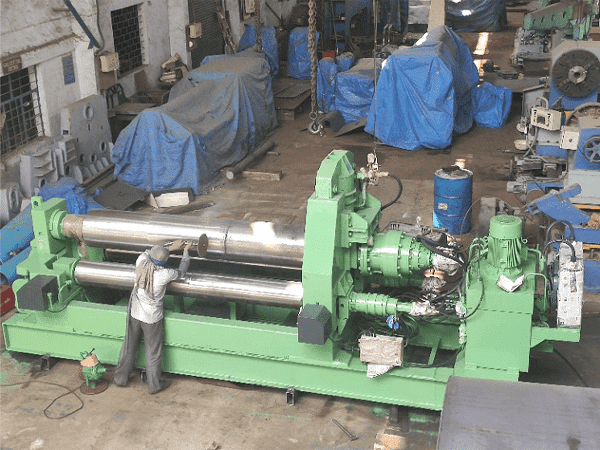

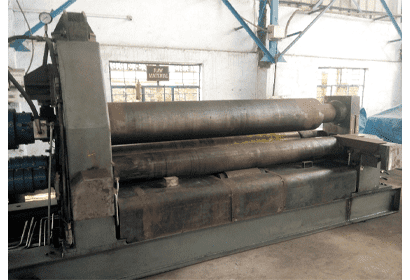

This is a machine model available with pre bending facility and most useful for one of / repetitive type of medium and heavy components.

The machine frame is fabricated from all tested steel plate material. A Die Penetration test is carried out on all weld joints to ensure sound weld quality This frame is subjected to stress relieving, sand blasting and epoxy primer painted for corrosion free long lasting machine life.( Primer paint 160 DFT) The complete body frame is machined in CNC machine to achieve built

A movable control desk is conveniently located on machine. The main panel start / stop buttons and roll rotation fucntion (Reverse / forward) is provided on the same. The Top roll left side position and right side position are indicated separately by four digital meters

A specially designed & built mechanism allows drop end frame to tilt down in horizontal position without much efforts (one person can perform job). No need to dismantle frame from main body like in conventional machine. The top roll can be tilted to great degree of inclination making it most convenient and ease to remove rolled shells without any difficulty

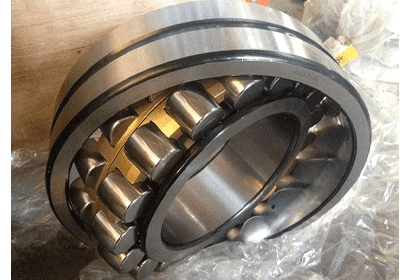

All our machine rolls are mounted in heavy duty roller bearings. Each roller is fitted with two bearing per side (four bearing per roller)

In this type machine all three rolls can be inclined to great degree This makes it most suitable for forming cones with wide diameter difference Also since the machine can work as a press too it can form cone up to full machine capacity If cones are made by press forming method Also a separate dual cone bending attachment can be provided for forming narrow angle cones