Work Piece Squaring

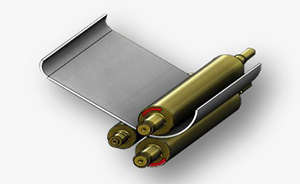

Leading Edge Pre Bending

Plate Training Edge Re Insert

Training Edge Pre Bending

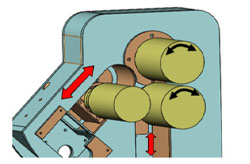

Rolling Start

Rolling In Progress

Rolling Complete

| 3R SP _ _ _ _ LAMN | 3R SP _ _ _ _ LAEM | |

|---|---|---|

| MODEL TYPE | MANUAL | ELECTRO MECHANICAL |

| CONTROLS | HAND WHEEL/PUSH BUTTON | PUSH BUTTON |

| PRE BENDING | YES | YES |

| RANGE | 1200 MM X 1 – 5 MM | 2000 MM X 1 – 6 MM |

| PRODUCTION RATE ACTUAL ROLLING TIME | 3 – 4 PCS/ HOUR | 8 – 10 PCS / HOUR |

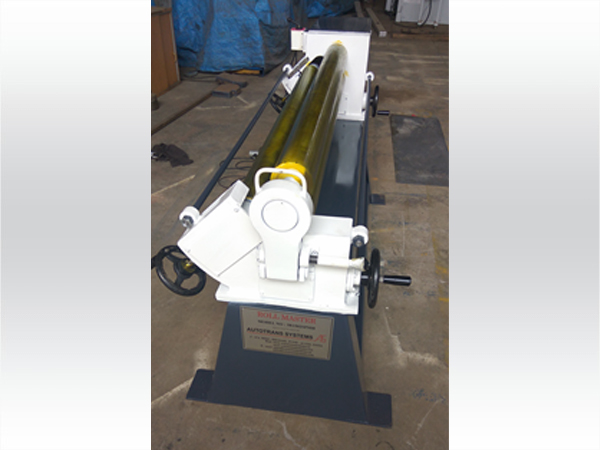

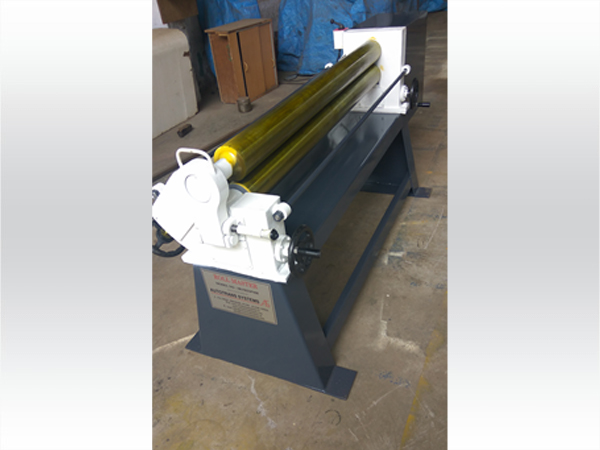

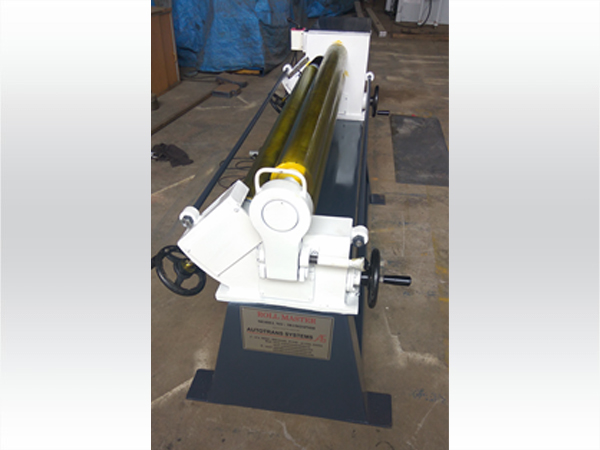

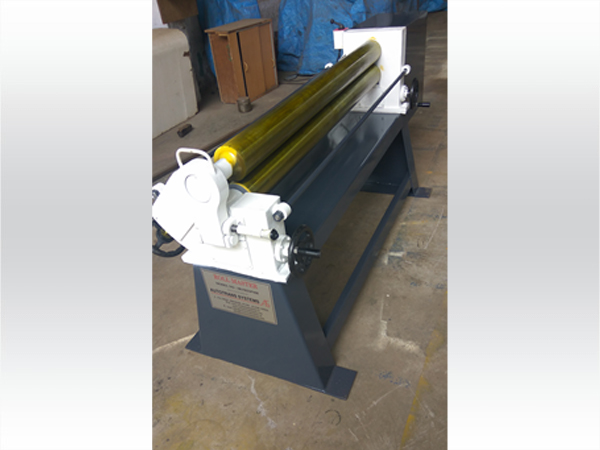

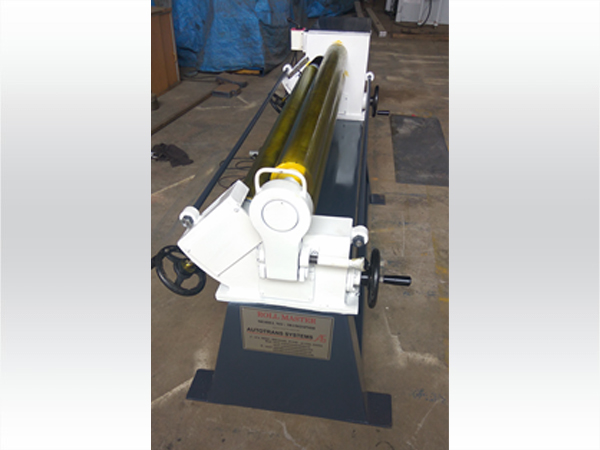

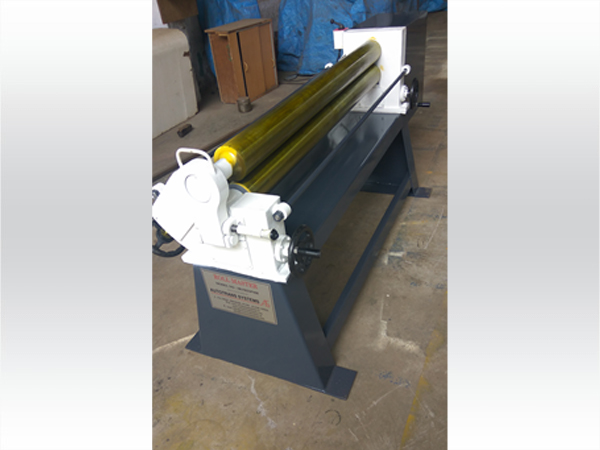

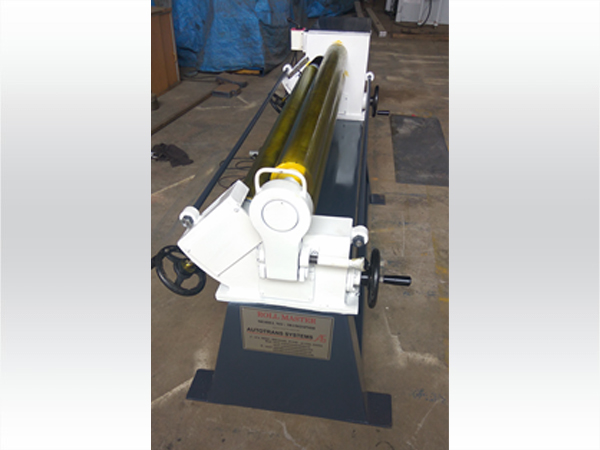

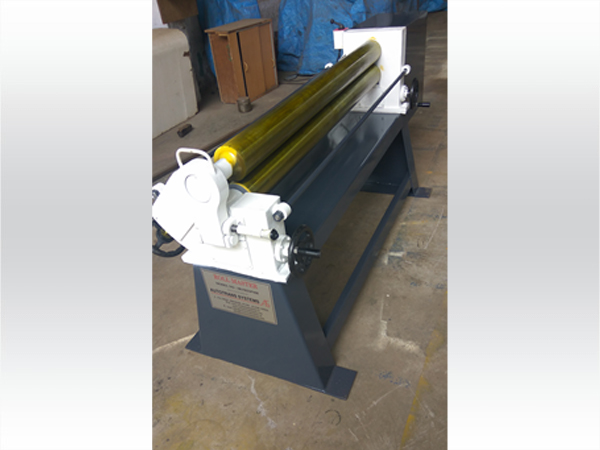

The machine is most economical model among all plate bending machine and is most useful for small fabrication shop. Both pre bending and rolling can be done in the same machine.

Autotrans Systems specializes in high-quality Three Roll Rolling Machine Manufacturer & Three Roll Bending Machine Manufacturer. Our team of talented engineers and state-of-the-art manufacturing facilities enable us to produce dependable and effective equipment that performs exceptionally well in a wide range of industrial applications. We provide Three Roll Rolling / Bending Machine Manufacturer in India. Get in touch with us right now to find out more about our equipment and how it may improve your bending processes.

The machine frame is fabricated from all tested steel plate material. A Die Penetration test is carried out on all weld joints to ensure sound weld quality This frame is subjected to stress relieving, sand blasting and epoxy primer painted for corrosion free long lasting machine life.( Primer paint 160 DFT) The complete body frame is machined in CNC machine to achieve built in accuracy.

Both bottom roll clamping and side roll up down movements are through hand wheel rotation.

A steel ruler is provided to ascertain side roll position and there by rolling diameter. The main panel start / stop buttons and roll rotation function (Reverse / forward) is provided on Machine frame itself.

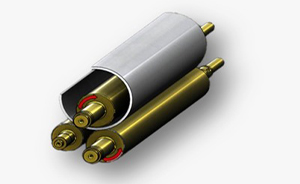

All our machine rolls are mounted in heavy duty roller bearings. Each roller is fitted with two bearing per side (four bearing per roller).

Both the top roll and bottom rolls are driven by separate gear box and motor directly mounted on roller shaft.