| Sr. No | Particular | Remark |

|---|---|---|

| 1 | PRE BENDING | Yes |

| 2 | ROLLING/BENDING | YES |

| 3 | MAX ROLL WIDTH | 3000 MM |

| 4 | MINIMUM THICKNESS | 0.5 MM |

| 5 | MAX. THICKNESS | 5 MM |

| 6 | PRODUCTION RATE | 2 – 3 PCS / MIN |

| 7 | MINIMUM ROLLING DIA | 25 MM |

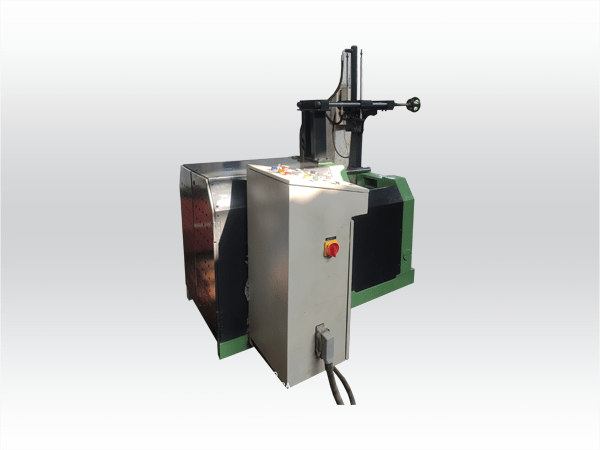

This machine is most suitable for pre pinching and rolling of sheet metal components up to 2000 mm width x 5 mmthk material.

Autotrans Systems is a top two Roll Sheet Rolling Machine Manufacturer with expertise in creating high-end machinery for a range of industrial uses. We provide dependable and effective solutions to satisfy the various rolling needs of our clients thanks to our cutting-edge manufacturing facilities and skilled engineering staff.

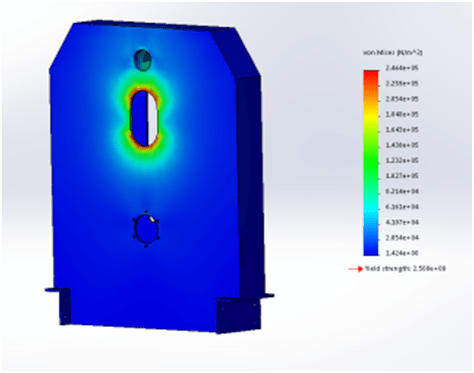

Simulation- All critical

components are verified &

analysis is done through

simulation software.

Safety factor is consider to

ensure long mechanical

working life

The machine frame is built from all tested steel plate material. The frame is subjected to stress reliving, sand blasting and epoxy primer painted for corrosion free long lasting machine life. The complete frame is machined in CNC machine to achieve built in accuracy

A control desk is conveniently located on machine. The main panel start / stop buttons and roll rotation function (Reverse / forward) along with Auto/manual selection button is provided on the same desk.

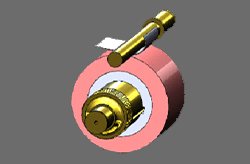

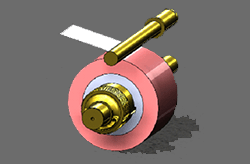

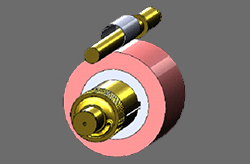

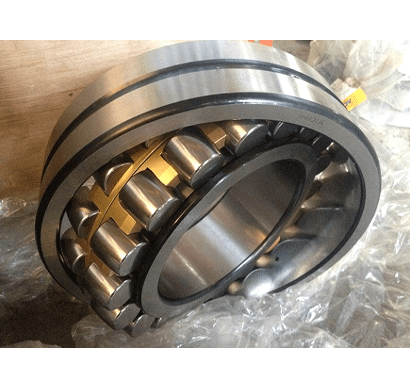

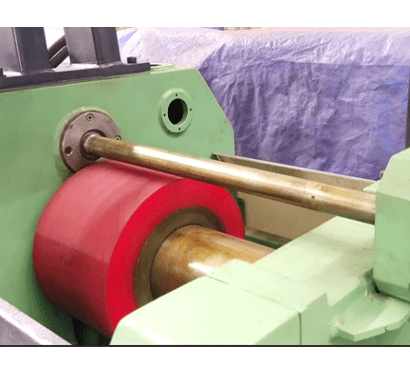

All our machine rolls are mounted in heavy duty roller bearings. Each roller is fitted with two bearing per side (four bearing per roller).

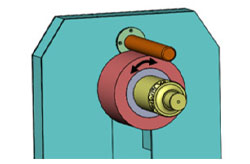

Rolling diameter as small as 25 mm also can be obtained with the help of special attachment Consistent same rolled sleeve output is guaranteed.

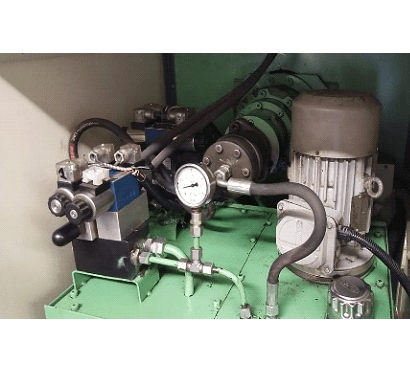

A specially developed Mechanical and hydraulic system can allow wide range rolling of different diameter without changing top spindle roll.

A high quality poly urethane roll of most appropriate hardness gives longer roll life and also gives best pre bending without any flat end.